February 15th, 2013 by

Within this article, HSDonline provides a full guide on Why the need for insect control. When a flying insect lands or feeds on un-hygienic substances, disease pathogens are transferred onto their numerous body hairs or are ingested into their gut. Since these insects are so mobile they can quickly move away from their disgusting habitats and carry the disease pathogens to the human food chain. If a fly manages to land directly onto food or a food preparation area then there is a good chance it will have contaminated it with a disease causing pathogen. There are many diverse types of disease causing organisms that have been linked with flying insects, they include:

- E Coli

- Salmonella

- Campylobacter

- Klebsiella

- Streptococci

- Meningitis

Flying insects are filthy creatures they live, breed and feed in disgusting areas and are at home living on decaying food, carcasses and human excrement. Flies have a disgusting digestive system. They cannot eat solid food, so they vomit on it to make it edible. They suck this liquid back up, all the while dropping excrement.

Food Hygiene Legislation

The main food hygiene laws in the UK are the Food Hygiene (England) Regulations 2006 (and equivalent regulations in Scotland, Wales and Northern Ireland) and Regulation (EC) No. 852/2004 on the Hygiene of Foodstuffs.

- The 2006 law is based on EU legislation that incorporates many points from previous UK food hygiene and safety acts

- It is a legal requirement for businesses to implement a food hygiene plan based on HACCP principles

- Flyscreens are a legal requirement where windows and doors open to the outside

- Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29th April 2004 of the Hygiene of Foodstuffs states:

- Premises and vending machines are, so far as is reasonably practicable, to be sited, designed, constructed and kept clean and maintained in good repair and condition as to avoid the risk of contamination, in particular by animals and pests. (Annex II Food premises: Chapter III: point 1)

- Adequate procedures are to be in place to control pests. (Annex II Food premises: Chapter IX: point 4)

- Those windows which can be opened to the outside environment are, where necessary, to be fitted with insect-proof screens which can be easily removed for cleaning. (Annex II Food premises: Chapter II: point 1(D))

HACCP (Hazard Analysis and Critical Control Points)

- All food businesses must put in place ‘food safety management procedures’ based on the principles of HACCP

- HACCP helps businesses to put procedures in place to control hazards

- Businesses must consider the control of pests in their HACCP plan, and maintenance records of any equipment (including flykillers) will become part of the plan

- If a pest control company is employed to monitor the premises on a regular basis, their reports should be kept as part of HACCP documentation

The Food Standards Agency provide further information on food hygiene regulation and good practice - www.food.gov.uk

Where is flying insect control required

Flying insects are recognised as a problem pest, both by businesses and their customers and are seen as an irritant at the very least and unhygienic and disease carrying at worst. Whilst legislation covers the use of flying insect control in specific circumstances, there are a number of wider applications where flying insect control can be used to protect your business and safeguard the comfort of your customers.  Food businesses

Food businesses

Hotels In addition to adhering to food hygiene legislation for preparation and storage areas, there are a number of other customer facing areas which may benefit from flying insect control. Decorative units can be discreetly positioned in lobbies, bars and restaurants to ensure that customers are free from irritating flying pests in all areas of the hotel. Flyscreens can be fitted on room windows to ensure that guest rooms can also be protected.

Hotels In addition to adhering to food hygiene legislation for preparation and storage areas, there are a number of other customer facing areas which may benefit from flying insect control. Decorative units can be discreetly positioned in lobbies, bars and restaurants to ensure that customers are free from irritating flying pests in all areas of the hotel. Flyscreens can be fitted on room windows to ensure that guest rooms can also be protected. Cafés & restaurants Whilst food hygiene legislation covers the areas that customers often can't see, the front-of-house area is where the customer judges the business on perceived hygiene and cleanliness. To ensure that customers are kept free from pests at every opportunity, discreet decorative units offer an ideal option for customer facing areas - Silent and subtle, they ensure that flying insect are dealt with quickly and quietly, allowing your customers to enjoy their experience.

Cafés & restaurants Whilst food hygiene legislation covers the areas that customers often can't see, the front-of-house area is where the customer judges the business on perceived hygiene and cleanliness. To ensure that customers are kept free from pests at every opportunity, discreet decorative units offer an ideal option for customer facing areas - Silent and subtle, they ensure that flying insect are dealt with quickly and quietly, allowing your customers to enjoy their experience.HSDonline, electric fly killers and insect control

HSD were one of the first companies to sell electric fly killers online in the UK. Prior to this it was only commercial outlets that had access to electric fly killers through trade wholesalers. Over the years HSD has sold tens of thousands of electric fly killers to home owners and business owners and this product range we have on offer has proved a tremendous success. HSD works directly with the manufacturers and are one of the only companies who are constantly developing and bringing new innovations to the Electric Fly Killer market. (HSD are bringing you the most comprehensive range of Electric Fly killers and other insect control products available in the UK today). Our own brand of Vermatik fly killers (here)are one of the most effective ranges of electric fly killers use for insect control on the UK market.

What is a fly control unit?

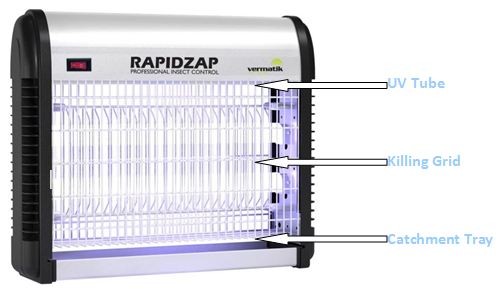

1.UV light attracts the flies ![]() UV Light bulb 2.The fly then either gets caught on the sticky glueboard or ‘zapped’ on the electronic grid, falling into a deep catchment tray Electric killing grid fly killers: Electric fly killers use UV light to attract flying insects to the unit, then use a killing grid to kill the insects, before retaining them in a catch tray to allow hygienic disposal. Electric fly killers are ideal for use in commercial back-room commercial front of house and industrial back-room areas. The most common type of insect killer sold in the UK is an 'electric killing grid' model.

UV Light bulb 2.The fly then either gets caught on the sticky glueboard or ‘zapped’ on the electronic grid, falling into a deep catchment tray Electric killing grid fly killers: Electric fly killers use UV light to attract flying insects to the unit, then use a killing grid to kill the insects, before retaining them in a catch tray to allow hygienic disposal. Electric fly killers are ideal for use in commercial back-room commercial front of house and industrial back-room areas. The most common type of insect killer sold in the UK is an 'electric killing grid' model.

Electronic insect killer:

The insect control via Electric Fly Killer Flying insects are drawn towards the unit, attracted by the special UV light inside, the majority of our tubes emitting UV at 368nm, proven to be the most insect attractive wavelength.

The insect control via Electric Fly Killer Flying insects are drawn towards the unit, attracted by the special UV light inside, the majority of our tubes emitting UV at 368nm, proven to be the most insect attractive wavelength.  A high voltage grid housed within the unit ‘zaps’ the fly dead. Dead flies are caught in a removable catchment tray at the bottom of the unit.

A high voltage grid housed within the unit ‘zaps’ the fly dead. Dead flies are caught in a removable catchment tray at the bottom of the unit.  Fly zapped by an electric fly killer An alternative to an electric killing grid is the more discrete glueboard insect control favoured in Southern & Central Europe. Glueboard Fly killers Glueboard fly killers use UV light to attract flying insects to the unit, then use a glueboard to retain the flying insects. As the insect is caught and retained whole, glueboard fly killers are ideal for more sensitive environments. Glueboard fly killers are ideal for insect control use in commercial front-of-house areas, commercial kitchens and industrial food preparation zones. The flies get stuck on the special glueboard housed within the unit, all our glueboards incorporate a highly attractive pheromone and utilise an easy peel protective sheet.

Fly zapped by an electric fly killer An alternative to an electric killing grid is the more discrete glueboard insect control favoured in Southern & Central Europe. Glueboard Fly killers Glueboard fly killers use UV light to attract flying insects to the unit, then use a glueboard to retain the flying insects. As the insect is caught and retained whole, glueboard fly killers are ideal for more sensitive environments. Glueboard fly killers are ideal for insect control use in commercial front-of-house areas, commercial kitchens and industrial food preparation zones. The flies get stuck on the special glueboard housed within the unit, all our glueboards incorporate a highly attractive pheromone and utilise an easy peel protective sheet.  A good insect control system: Glueboard The flies remain stuck to the glueboard, which should be changed approximately every six weeks. For more details, have a look to our range of Glueboard fly killers.

A good insect control system: Glueboard The flies remain stuck to the glueboard, which should be changed approximately every six weeks. For more details, have a look to our range of Glueboard fly killers.

What is UV Light?

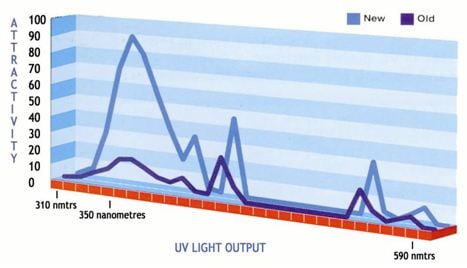

Insects are attracted to all light but over the years research has proven that insects are particularly attracted to blue ultra violet light at a UV wavelength of approximately 368 nanometre:  What is UV light? HSDonline.co.uk offers users a wide choice of 368nm blue & Green UV lamps in both standard or shatterproof options (Replacement UV Tubes) as well as a huge range of insect control products. We recommend that UV tubes (fly killer bulbs) are changed every 12 months to ensure maximum efficiency. The levels of UV produced by fluorescent tubes deteriorates throughout the life of the tube. Whilst the tube will continue to glow indefinitely, after approximately 8,000 hours the amount of useful UV drops to a level where it is no longer attractive to flying insects. Shatterproof tubes provide peace of mind in sensitive areas by retaining glass shards if the tube is broken. Shatterproof tubes MUST be installed in areas operating a ‘glass free policy’. The Fluorinated Polymer (FEP) material used for all sleeving is designed specifically for optical transmission and allows 97% of effective UV light to pass through the coating. As a result, the maximum possible amount of useful UV irradiance passes through the sleeving to effectively attract insects. With only 3% of the irradiance being absorbed into the material , the structural integrity of the sleeving is maintained for the full 12 month life of the tube, preventing discolouring and ensuring all glass shards are retained in the event of a breakage.

What is UV light? HSDonline.co.uk offers users a wide choice of 368nm blue & Green UV lamps in both standard or shatterproof options (Replacement UV Tubes) as well as a huge range of insect control products. We recommend that UV tubes (fly killer bulbs) are changed every 12 months to ensure maximum efficiency. The levels of UV produced by fluorescent tubes deteriorates throughout the life of the tube. Whilst the tube will continue to glow indefinitely, after approximately 8,000 hours the amount of useful UV drops to a level where it is no longer attractive to flying insects. Shatterproof tubes provide peace of mind in sensitive areas by retaining glass shards if the tube is broken. Shatterproof tubes MUST be installed in areas operating a ‘glass free policy’. The Fluorinated Polymer (FEP) material used for all sleeving is designed specifically for optical transmission and allows 97% of effective UV light to pass through the coating. As a result, the maximum possible amount of useful UV irradiance passes through the sleeving to effectively attract insects. With only 3% of the irradiance being absorbed into the material , the structural integrity of the sleeving is maintained for the full 12 month life of the tube, preventing discolouring and ensuring all glass shards are retained in the event of a breakage.

Understanding and operate the flying insect control

Because there are so many different species and their behaviour subject to so many different influences; flying insect control is not a simple problem. Just hanging a few electric insect killers at random will not automatically solve it. Firstly, identify the problem pests that need to be controlled  Insect Control: Identify the problem... Then all conditions contributing to a problem must be identified and corrected. These can include the type and position of lighting, location of trash disposal facilities, sanitation and chemical procedures, inadequate physical barriers, the ecology of the surrounding area and more.

Insect Control: Identify the problem... Then all conditions contributing to a problem must be identified and corrected. These can include the type and position of lighting, location of trash disposal facilities, sanitation and chemical procedures, inadequate physical barriers, the ecology of the surrounding area and more.

Once the insect population has been reduced by corrective measures, the proper equipmen can be positioned to deal with the insects that remain:

Electric Fly Killer or Glueboard ?

Electric Fly Killer or Glueboard ?  Area Coverage: The coverage areas quoted should be used as a general figure not as an exact quotation. The distance at which an insect responds is determined by lamp type and unit design, but also by the number of insect killers:

Area Coverage: The coverage areas quoted should be used as a general figure not as an exact quotation. The distance at which an insect responds is determined by lamp type and unit design, but also by the number of insect killers:  Visual Acuity: Most insects do not respond to insect killers more than 30 meters away, houseflies appear to respond at about 10 meters. Nature of the Fly: Many flies will respond immediately to a insect killer, some will not.

Visual Acuity: Most insects do not respond to insect killers more than 30 meters away, houseflies appear to respond at about 10 meters. Nature of the Fly: Many flies will respond immediately to a insect killer, some will not.

How to position a fly killer?

Every application is unique, so each situation requires an individual assessment for fly killer sitting, however, there are basic principals that should be followed:

- Recommend enough EFKs to cover the area to be protected in line with the recommended coverage guidelines for each model

- Install EFKs away from sources of light competition, such as windows, doors and high powered luminaires

- Consider sources of heat and airflow, such as heaters / AC units

- Don’t install EFKs directly above sensitive areas, such as food preparation areas

- Glueboard units should be used in sensitive applications such as food preparation or production areas

- Consider access for installation and future servicing

- Wherever possible, fly killers should be positioned at 90° to sources of natural light, such as windows, doors and skylights

- Fly killers should be positioned in between potential entry points, so as to intercept flying insects before they reach sensitive areas

- Fly killers should not be sited either too high or too low in the area to be protected, with an optimum height of around 2m, for most flying insect species.

A list of Don’ts:

DON’T: use ceiling hung insect killers over food processing areas. DON’T: use insect killers where their attractant light shines directly out of windows. DON’T: place insect killers in direct sunlight. Sunlight contains all the wavelengths of energy that both humans and insects see as light, including the wavelengths that attract insects to fly-traps.

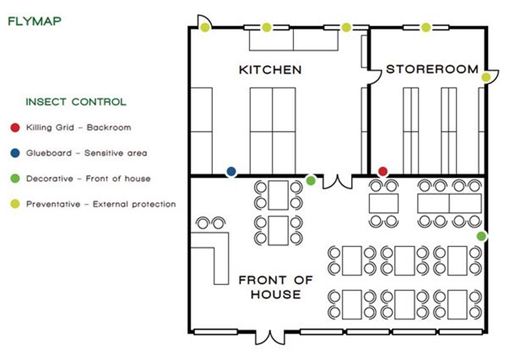

Insect Control 'FLYMAP' to spot strategic places

Insect Control 'FLYMAP' to spot strategic places

What are the critical areas you must protect?

These critical areas tend to be the ones where the fly will be attracted. (E.g.:"where the food or ingredients are exposed").

- The food preparation areas in a kitchen or shop.

- The food processing/packing areas in a factory.

Anywhere where food is displayed (particularly important in supermarkets and fast food outlets).

Are there any public areas that need protecting?

This essentially means dining rooms or restaurant areas in shops/restaurants or food courts in malls or supermarkets. The general public are now beginning to realise just how disgusting flies are so it is now essential to protect these areas. It shows the customer that you are protecting them against the disease spread by flying insects. The best units to use here are the decorative units offering discreet insect control protection.

Are there any unusual circumstances which need to be taken into consideration?

- Some environments, particularly food processors and distilleries, have a high dust content.

- Particularly high pressure water hosing. Again, this is often evident in food processing environments where high water pressure is often used in cleaning.

- Food processing areas are often hot and humid, and this humidity can create problems with electrical equipment

These three areas require specialist fly killers, as standard machines will often not withstand such harsh conditions. IP65 – Protection against foreign bodies (dust and water) ATEX – Protection against the risk of explosion These can be viewed at http://www.hygienesuppliesdirect.com/th/fly_killers_specialist If you require further information on our range of electric fly killers or anything related to a insect control, please call our experts on 0800 091 31 71 (freephone).

**Thanks to Paul Cook (business development manager) for sharing his knowledge**

Enjoyed? Check out our latest posts